The fused zircon corundum brick is a white solid formed by pure alumina powder and zircon sand containing zirconia of 65% and about 34% of silica in the electric melting furnace and then injected into the mold to be cooled.

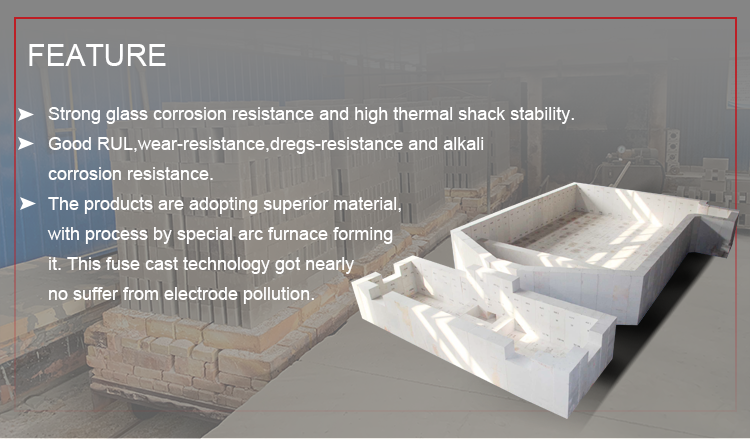

Zircon brick / Zirconia bricks have the advantage of mechanical strength, excellent stability to thermal shock, resistance to

corrosion, high refractoriness under load and inertness, high density, etc. It is widely used in glass furnace, non-ferrous metal smelting furnace, and pure steel furnace. Please see listed applications on lower right of this page.

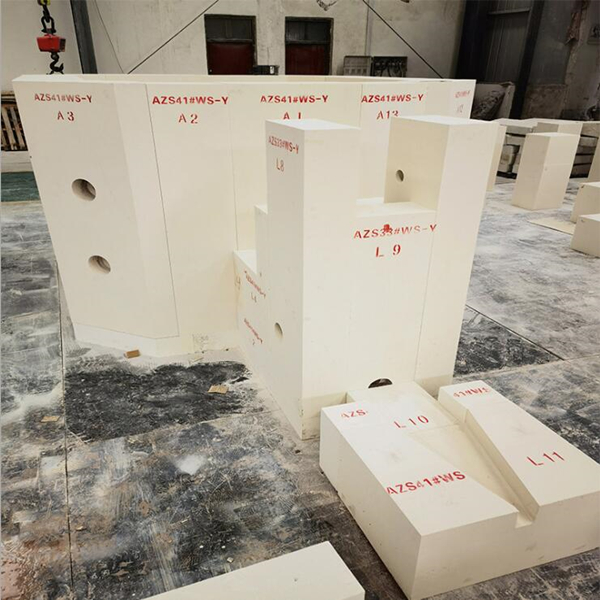

TK BRICKS can produce serious fused cast 33#,36#,41#AZS block for glass furnace.

We can produce common shaped and irregular shaped refractory brick.And we can adjust our specifications for your application.

Zircon brick / Zirconia bricks have the advantage of mechanical strength, excellent stability to thermal shock, resistance to

corrosion, high refractoriness under load and inertness, high density, etc. It is widely used in glass furnace, non-ferrous metal smelting furnace, and pure steel furnace. Please see listed applications on lower right of this page.

TK BRICKS can produce serious fused cast 33#,36#,41#AZS block for glass furnace.

We can produce common shaped and irregular shaped refractory brick.And we can adjust our specifications for your application.

Wechat Us

Wechat Us